STEAM TURBINE ALIGNMENT

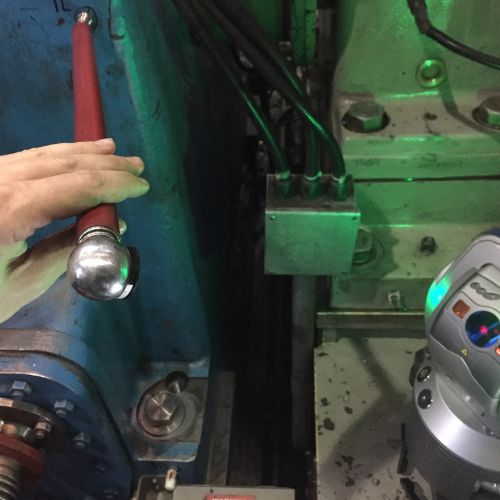

ACQUIP have considerable experience for steam turbine internal laser alignment. Our service is extremely quick, accurate, and effective and dramatically decreases the possibility of human error. It saves days when compared to tight wire and optical methods.

Our Services for steam turbine internal alignment include:

GE steam turbines (Diaphragm Alignment)

Westinghouse steam turbines (Blade Ring Alignment)

Theoretical Tops On (Express Alignment)

When our Service Engineers perform steam turbine internal laser blade ring alignment, they produce accuracy to within 1 micron. It is achieved by first shooting a laser line through the approximate center of all blade rings or diaphragms in order to create a static point of reference. Our adjustable bore specific bracketing system is then employed in order to probe the surface of each of the diaphragms, glands, nozzles, oil deflectors, bearing brackets, and ascertain the exact center position.

The data points are recorded in the computer and adjusted for rotor sag, dynamic movement, and tops on to tops off deviation. The appropriate line for the machine is then determined and all components are laser aligned to the correct position.

GAS TURBINE ALIGNMENT

ACQUIP's laser internal gas turbine alignment service is extremely quick, accurate, effective and dramatically decreases the possibility of human error. This can mean shaving days off the process when compared to tight wire and optical methods.

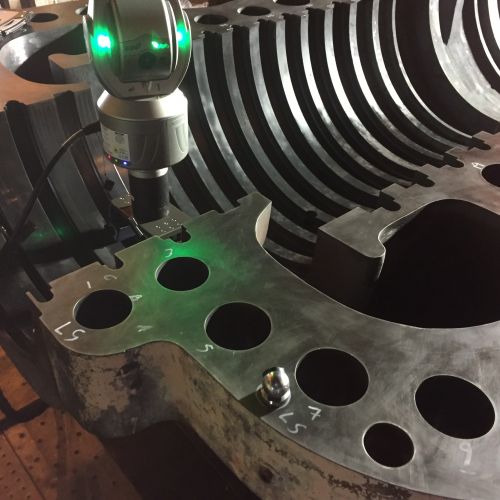

When you apply laser internal gas turbine alignment, you get accuracy to within 1 micron. It is achieved by first shooting a laser line through the approximate center of the bearings, compressor, and shroud in order to create a static point of reference. Our adjustable bore specific bracketing system is then employed in order to probe the surface of each of the compressor section, shroud, or bearing brackets to ascertain the exact center position. Our proprietary bracketing can be used while the compressor blades are installed or removed.

The data points from the laser internal gas turbine alignment are recorded in the computer and adjusted for bearing preset conditions. The appropriate line for the machine is then determined and executed upon.

With ACQUIP, the internal gas turbine alignment process is quick, cost-effective, and produces precise repeatable readings.

SHAFT ALIGNMENT

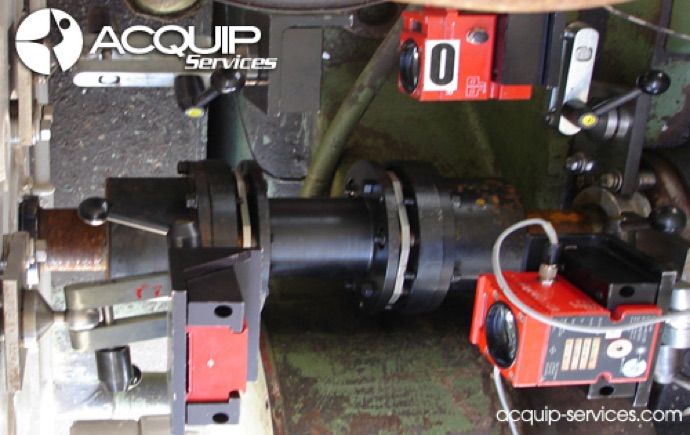

ACQUIP offers comprehensive laser shaft alignment that is proven, it is the standard and most effective method for coupling alignment.

Using the most advanced and precise laser alignment systems on the market. ACQUIP can quickly improve the running condition and dependability of your machines. Shaft alignment is one of the mission critical components for optimum performance.

Performing correct shaft alignment saves time and money. Misalignment is the most common cause of machine vibration. Understanding and practicing the fundamentals of shaft alignment is the first step in reducing unnecessary vibration, reducing maintenance costs, and increasing machine uptime.

BORE LASER ALIGNMENT

ACQUIP's laser bore alignment service is extremely quick, accurate, and effective. Laser bore alignment will also dramatically decrease the possibility of human error.

Accuracy to within 1 micron is achieved by first shooting a laser line through the approximate center of all bores in order to create a static point of reference. Our adjustable bore specific bracketing system is then employed in order to probe the surface of each of the bores and ascertain the exact center position.

The data points are recorded in the computer and adjusted for machine specific presets. The appropriate line for the machine is then determined and executed upon.

With ACQUIP , the bore alignment process is quick, cost-effective, and produces precise repeatable readings.The speed, accuracy, and effectiveness of the ACQUIP laser bore alignment method can also be applied to:

Turbine

Reciprocating Compressors

Diesel Engines

Centrifugal Pumps

MACHINE TRAIN ALIGNMENT

ACQUIP Arabia offers comprehensive machine train laser alignment that is proven to eliminate the most common cause of machine vibration. When performing machine train alignment it is important to take measurements at each coupling before performing any moves, a proper coupling alignment increases mean time between failures, bearing and seal life, and decreases power loss.

We can quickly improve the running condition and dependability of your machines. Our techniques allow for minimal moves, choosing the smallest and easiest points to be movable, and making the others stationary to get the machine to optimal alignment conditions.

DYNAMIC MOVEMENT / THERMAL GROWTH

ACQUIP knows that it is critical to have Thermal Growth Monitoring of machinery aligned at hot operating conditions, not just cold conditions. It is essential that machines be monitored from cold to hot operating conditions in order to properly adjust for thermal growth as well as incalculable relative torque movement.

ACQUIP uses the most advanced laser-based alignment systems to configure your machines optimal coupling alignment targets throughout its thermal range, it facilitates maximum running efficiency and productivity.

Dynamic movement is due to a combination of thermal and torsional stresses introduced to the machine after start up. The only way to compensate for how much these forces affect your machine is to measure them.

We use a laser based monitoring system to incrementally measure the relative movement of your machine from rest to hot operating conditions. This ensures that all dynamic movement is recorded and accurate alignment targets can be developed from the information.

All data is time stamped in order to correlate alignment changes to events that occur in your process. Our technicians have experience with a wide variety of machines and we know how to accurately measure dynamic movement without damaging your machines.

VIBRATION ANALYSIS / PREDICTIVE MAINTENANCE

ACQUIP provides vibration analysis for an acute problem or data collection on contract basis for trending and predictive maintenance. This service provides early warnings of predictable problems with rotating equipment.

ACQUIP vibration services has the equipment, experienced personnel and the expertise to perform machinery vibration analysis.Routine vibration surveys are conducted with a portable digital data collector/FFT analyzer and a computer program designed to manage the database for trending and spectral analysis. Once problems are identified, reports are generated to produce follow through and feedback.

These reports are designed to give management recommendations such as:

Ratings on the severity of the vibration

How long the vibration has trended upward

Time projections until alarm or danger set points are reached

Performance of regular routine vibration surveys will result in:

Decreased downtime (increased availability).

Increased production and efficiency.

Decreased maintenance cost.

BORESCOPE INSPECTION

ACQUIP, provides borescope inspection services to industrial customers such as electrical power plants, petrochemical facilities, manufacturing, municipalities and process plants. Industrial customers typically have periodic requirements to inspect boilers, heat exchangers, turbines and pipes. In addition to periodic inspections, emergency requirements may arise if an unplanned shut down is caused by an industrial system and internal inspection needs to be completed before the plant is able to return to operation.

Borescope services can be scheduled ahead of a planned outage. When planned properly ACQUIP, is able to complete several borescope inspections at a single facility to maximize the customer’s investment and return the plant back to operation faster and more safely.

Foreign material exclusion or retrievals is part of borescope inspection services as well. ACQUIP, is well aware that tools or foreign objects are dropped into turbines, pipes, and other impossible to reach areas. Loose parts may also be discovered in remote locations. Foreign material and loose parts must be removed from industrial systems before a plant can return to operation. ACQUIP, is now able to offer retrieval services to locate and remove these items without tear-down of equipment and plant systems.

3D SCANNING

ACQUIP services proudly introduces our new 3D scanning services with the FARO FOCUS 3D tool, which uses one of the most advance technologies of its type. Our 3D services allow you to accurately document As-Built conditions, simulate components in 3D for installation purposes and validate part designs by using reverse engineering. We can even inspect deflection on complex surfaces.

The ACQUIP Services - 3D Laser Scanning benefits include:

High-speed 3D advanced technology

Long range and easy measurement of large rotating equipment

Reduction of production downtime and prevention of errors

Highly accurate in providing dependable results

Elimination of rework, which leads to cost-effective processes

Access to speedy data Management